One of the primary regulations we must understand when considering responsible chemical management and the materials used in printing inks is the Toxic Substances Control Act (TSCA). The TSCA is a United States federal law that regulates the production, import, use, and disposal of chemicals. It aims to protect human health and the environment by ensuring that chemicals are properly

- The effective management of color tolerances in printing is essential for accurate and consistent color and to guarantee printed colors match the intended ones. However,

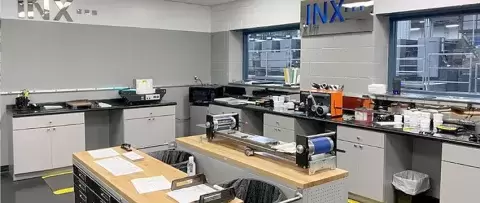

- Several issues can affect print quality and ink costs on any given job. As an ink provider, we at INX have a front-row seat to the challenges many printers and converters

- Effective management of an ink room presents a multifaceted challenge. By incorporating inplant operations onsite, printers can optimize production, increase print quality,

- Many print service providers are familiar with the term G7, but what does it actually mean? In short, G7 is a calibration process used to improve the printing consistency and

- Ink quality, and the way it is used in the printing process, is a key component of successful printing. Strong results require a consistent approach and knowledge of

- Just like getting an oil change for your car, performing standardized maintenance on printing equipment is an effort that maintains the value of the equipment itself. And,

- For any PSP (Print Service Provider) operating today, the quest to achieve exemplary, repeatable color should involve neither mystery nor miracle. As printing has become

- The quest for quality color is an essential part of successful print production, and the thoughtful use of color standards can increase quality, eliminate spoilage, and

- Consistently producing a client’s exact color specifications requires a predictable color management system. As a leading ink and coating supplier with a team of Color