What are the Advantages of Digital Printing?

Increase packaging customization, supply chain efficiency, and sustainability performance

Operational efficiency, speed-to-market, customization, and an improved environmental footprint are just a few of the benefits realized from digital printing. And, although digital printing has been used in the packaging industry for years, today’s growing demand for personalization, sustainable printing, and optimized supply chains are contributing to its future market growth.

What is digital printing used for?

Digital printing is one of the most popular methods for printing small production runs. Compared to conventional printing methods such as offset printing, it provides more flexibility and the ability to print on demand. This allows printers to print small batches and keep less inventory, lowering costs associated with handling and storage. Items will only be printed as needed. Digital printing is ideal for you project if you have a small print job, require customization or personalization and are pressed for time.

Advantage #1: Increased personalization capabilities

We all know that customer experience is a critical component in any business' success. Brand owners are continually looking for new opportunities to engage with customers by offering distinctive and personalized product versions and customized messaging. NAPCO Research conducted a study on the digital printing opportunities in packaging production. They surveyed package printers and converters as well as brand owners. The study showed that 79% of brand owners agreed that packaging is a key marketing tool for their company and they preferred to work with packaging printers and converters that offer digital printing1.

In the same NAPCO study, packaging printers indicated that customer demand for shorter runs to test packaging is both common and increasing. Digital printing makes producing smaller quantities of labels and packaging easier and more affordable. This allows brands to test packaging options and select the most impactful, targeted, and personalized packaging for each of their customer segments and purchase channels.

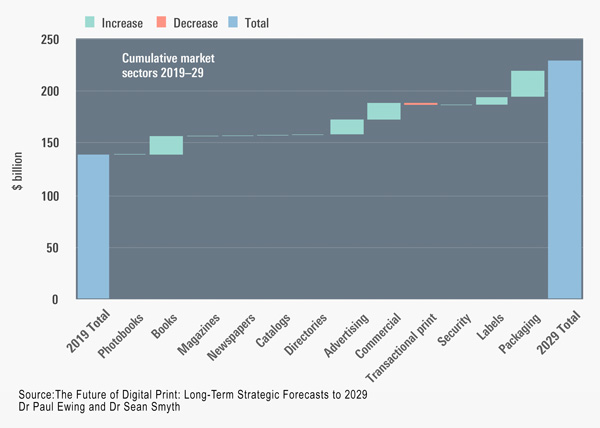

As brand owners continue to use packaging as a method of promotion and personalization, digital printing expertise for packaging printers and converters is becoming the norm rather than the exception. Digital printing will continue to expand and will be used with a wide variety of packaging substrates, including corrugated, flexible packaging, and more. According to the report The Future of Digital Print: Long-Term Strategic Forecasts to 2029, published by Smithers Pira, digital print will take a growing share of the packaging print market, growing to $32.5 billion in 2029.2

As a leading global manufacturer of digital inkjet inks and coatings for alternative OEM, industrial, specialty, and custom digital print applications, INX is well-prepared for the ongoing growth of digital print on a variety of packaging and label substrates. Customers use our inkjet formulations to produce high-performance, high quality digital printing of short run labels, metal packaging, point of sale board, corrugated boxes, folding cartons, and more. And, we have the largest line of inkjet inks and coatings, including:

- XJL UV Digital Inks for Label Printing

- BSR UV Digital Inks for Corrugated Printing

- WXKC Digital Inks for Flexible Packaging

- NWUV Digital Label Inks

- CPUV Digital Inks for Cylindrical Printing on Metal

- MEUV Digital Metal Inks for Metal Packaging

- TRIANGLE® Alternative Inks for Graphics and Signage

In this informative webinar INX presents a case study with Gabriel Perez of Bay Cities Packaging & Design as they set out to find a digital printer for corrugated. In this video Gabriel will walk you through the decisions and issues his company went through as they selected a digital printer and ink manufacturer that would fit their production needs. The INX team worked closely with Bay Cities and supported them throughout the process and installation of their Barberan Jetmaster 1750.

VIDEO

How Bay Cities chose a digital printer and ink company that met their print needs.

Watch Case Study

Advantage #2: Improved supply chain efficiency

Supply chain disruptions have become a major issue for many companies. For the first time in many years, supply chain challenges have directly or indirectly impacted the bottom line of several well-known companies.3 As brand owners, package printers, and converters strive to increase their supply chain efficiency by producing their work faster and implementing on-demand and just-in-time models, just-in-time production is required – which is where digital printing shines. The NAPCO survey previously referenced asked brand owners to select their companies’ top packaging challenges. As the graph below shows, improving their supply chain efficiency and responsiveness topped the list.

Key Brand Owners' Challenges

source: Napco Research

Digital printing makes it easier for brands and packaging printers to adjust to fluctuating demand. A recent report on the long-term forecast of digital print states that “The most significant change for digital printing over the next ten years will be through developments integrating digital print, particularly inkjet, into broader production systems including workflow and finishing to simplify and speed up time-to-market for many print products.”4 Digital print systems enable packaging printers and converters to eliminate plate and tooling costs and allow rapid job changeovers.

Digital print technology continues to evolve as advanced manufacturing technologies such as Artificial Intelligence (AI), cloud based data-mining, and robotics are embraced. At INX, we are seeing packaging converters utilize hybrid analogue/digital presses which combine the benefits of both technologies.

Advantage #3: Achieve sustainability and environmental objectives

Today’s brands are challenged to improve their environmental impact and establish and meet a number of sustainability objectives. All of the 25-largest CPG companies have made commitments to increasing recyclable content, minimizing packaging, or reusing material. Eighty percent (80%) of those companies are working toward fully recyclable packaging for all of their products by 2030.5

Consumers are also influencing the drive for eco-friendly packaging. A McKinsey study conducted in 2020 indicated that consumer concerns about the impact of packaging are spread among a variety of factors, as seen in the chart below:6

Concern over environmental impact of product packaging

(% of respondents)*

* Question: Overall, how concerned are you with the environmental impact of packaging?

Source: McKinsey Packaging Survey 2020

Digital printing is often considered more sustainable than other printing processes for a number of reasons. Digital printing produces less CO2 emissions than traditional presses. Additionally, the ability to print short runs can reduce or even eliminate the waste and inventory space that is created from products that become obsolete. Furthermore, digital printing eliminates the need for printing plates and make-ready waste is significantly reduced. At INX, delivering innovative, safe, and sustainable solutions that enhance the customer experience is our top priority. We want consumers, brand owners, and package printers/converters to feel confident in their product choices; and that’s why we develop our products to have minimal impact on the environment without sacrificing machine, processing, and end-use product performance.

Conclusion: Digital printing offers many benefits

The evolution and growth of digital printing offers significant benefits and opportunities for package printers and converters to support their clients’ packaging and operational strategies. Brand owners are embracing digital print and leveraging it to enable affordable, customized, short-run production to test packaging concepts, better manage their supply chains, and improve their sustainability and environmental performance. At INX, our chemists, engineers, and software experts provide a full range of products and support for customers wanting to realize the benefits of digital printing, including customization and integration of digital capabilities into new or existing printing operations.

1 Digital Packaging: The Time is Now!; Published by NAPCO

2 The Future of Digital Print: Long-Term Strategic Forecasts to 2029; Dr Paul Ewing and Dr Sean Smyth; Published by Smithers Pira

3 Why supply-chain problems aren’t going away; TheEconomist.com; January 29, 2022

4 The Future of Digital Print: Long-Term Strategic Forecasts to 2029; page XXIV, Dr Paul Ewing and Dr Sean Smyth; Published by Smithers Pira

5 Consumer Brand Association; Creating a sustainable future, through increasing recyclability and reimagining the recycling system

6 Sustainability in packaging: Inside the minds of US consumers; McKinsey.com