The Benefits of Gas Barrier Coatings for Packaging and Print Service Providers

Extending the shelf life of products

Sustainability and food safety concerns in the food packaging industry is a hot topic and is driving the use of functional materials to improve recycling and preserve food. One of the most important factors for assuring the safety and quality of food—as well as the recyclability of the package—is the appropriate selection of packaging materials such as the substrate, (paper and paperboard, plastics, glass, and metal) and the functional inks and coatings that decorate the package—most importantly the barrier properties.

Typical Barrier properties for the food packaging system typically fall into the gas barrier property, mechanical, thermal, rheological, morphological, optical, and other product resistant barrier properties. The Gas barrier property is often considered as the most important factor to reduce food waste and extend the shelf-life of food products. It also has the added benefit of making the package easier to recycle.

What is a Gas Barrier Coating?

Gas Barrier Coatings (GBCs) are thin films applied to packaging materials such as paper or plastic, to impede the passage of gases into or out of the package. They are highly durable barrier coatings, and their usage is growing – especially in food packaging applications.

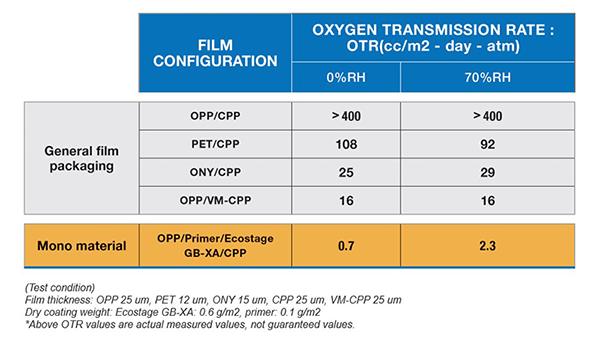

Oxygen barrier coatings specifically are formulated for drastically low oxygen transfer rates (OTR) which enables extended shelf-life, food safety and mono-material packaging. This makes them the right choice for many food and laminate structures applications.

LINK

Ecostage extends shelf life and enables mono-material packaging

See if Ecostage is <br/> right for you

Benefits of Gas Barrier Coatings

Barrier coatings are becoming an essential part of packaging and printing. They provide a functional layer between the substrate and the package's contents. By protecting packaged materials from the elements, barrier coatings can help maintain the quality of the packaged product and extend its lifespan. They also help make packages easier to transport and improve recycling with mono-material packaging, It is more important than ever for packaging and print service providers to understand the benefits they provide.

Extending Shelf Life

A significant benefit of using GBCs on packaging materials is that it allows for extended shelf life for food products. By slowing down the rate at which oxygen enters or leaves the package, GBCs can help prevent oxidation and spoilage caused by exposure to air. INX Ecostage GB-XA oxygen barrier coatings drastically improves the oxygen transmission rate of flexible packaging materials and offers a viable alternative to existing film options. The coating provides excellent barrier performance on Polyester and polyolefin films with dry film weights as low as 0.6 g/m2 (dry), significantly extending the shelf life of many types of foods such as cereals, snacks, and confectionery items.

Reduce Product Waste & Damage

An additional benefit of GBCs is their ability to extend the shelf life of a product and reduce product waste due to spoilage or damage while still providing superior product protection. This makes GBCs an attractive option for any business looking to save on shipping and storage costs while ensuring their products remain fresh and safe for consumers.

Package Lightweighting

The food & beverage industry is shifting from traditional packaging formats to lightweight and easy-to-transport ones. Barrier films help cater to this demand as they are lightweight compared to rigid packaging and eliminate the use of glass and cans, which increase the weight of the packaging.

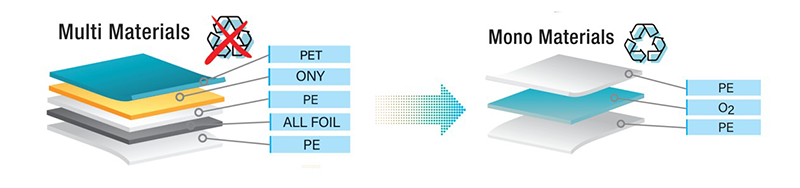

Improve Sustainability

Because providing the proper barrier properties often leads packaging producers to combine certain materials to get the best combination of barrier, physical, and aesthetic properties, these multi-material combinations can be hard to recycle since their materials are so dissimilar that they cannot be recycled together. Gas barrier coatings can be used in mono-material structures and do not impact recycling like multi-material packaging.

In a typical example, a multi-material laminate composed of PET/PE can be replaced with a barrier-coated OPP/CPP or OPE/PE structure. This new structure makes recycling easier by using similar materials while still maintaining oxygen barrier properties of other multi-material structures.

Conclusion

Barrier coatings are an excellent way for packaging and print service providers to protect the packaged product, extend shelf life and reduce food waste. They also make the package lighter, easier to transport and have the benefit of improved recycling. Packaging and print service providers can ensure they provide their clients with products that meet the customers’ needs while offering sustainable, recyclable alternatives over typical non-recyclable ones contributing to a more circular economy.

![Shrink Labels and Recycling [Shrink labellled bottles]](/sites/default/files/styles/large/public/2024-04/INX_shrink_blog850x360.jpg?itok=Qsx6qEqs)